Our Services

At Mag Motor Engineering, we specialize in the electromagnetic design and optimization of high-performance electric motors. Whether you are developing high-torque actuators for advanced robotics or high-efficiency traction motors for electric vehicles, we turn complex requirements into manufacturable, optimized reality.

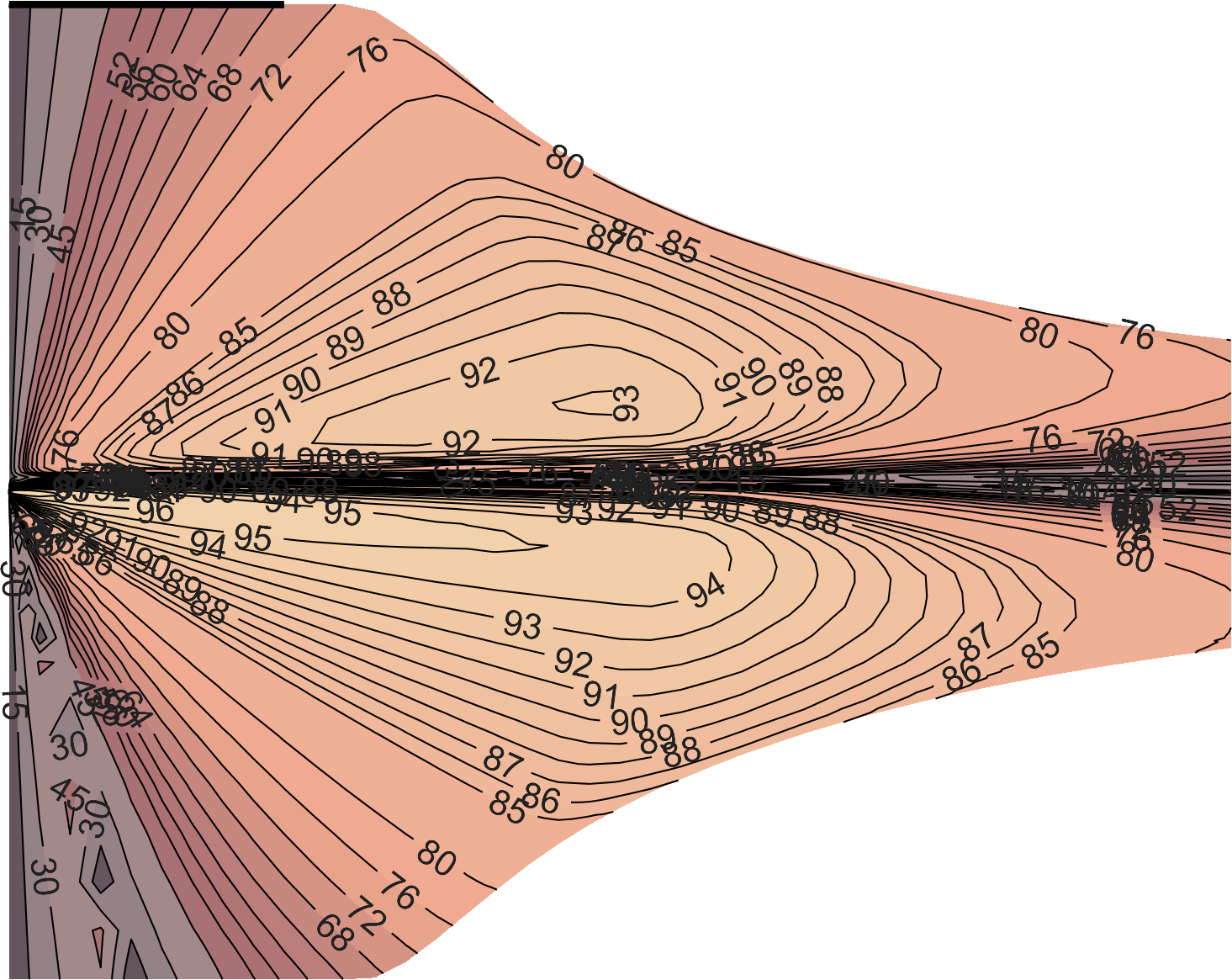

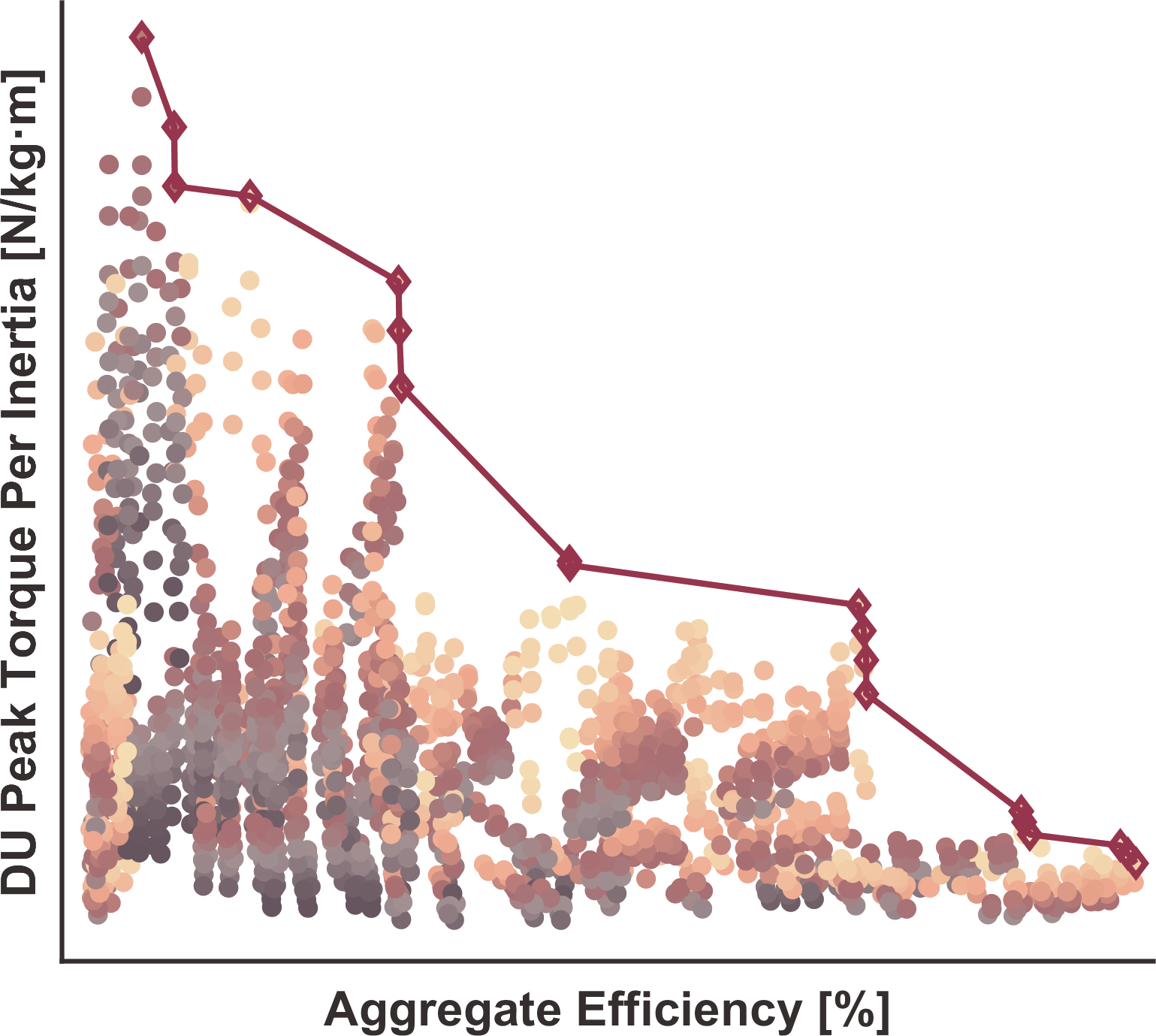

We don't just design motors; we use data to discover the perfect balance between power, weight, efficiency, and cost.

Custom Electromagnetic Design

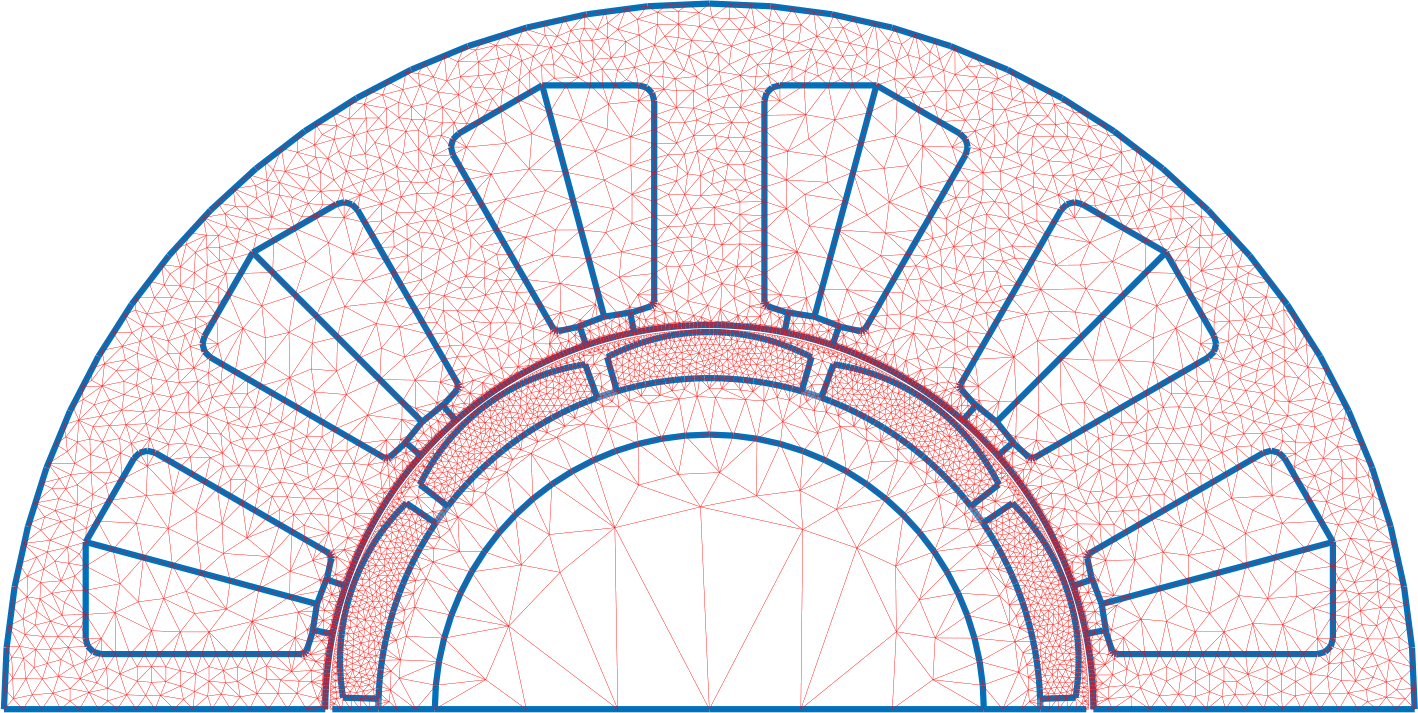

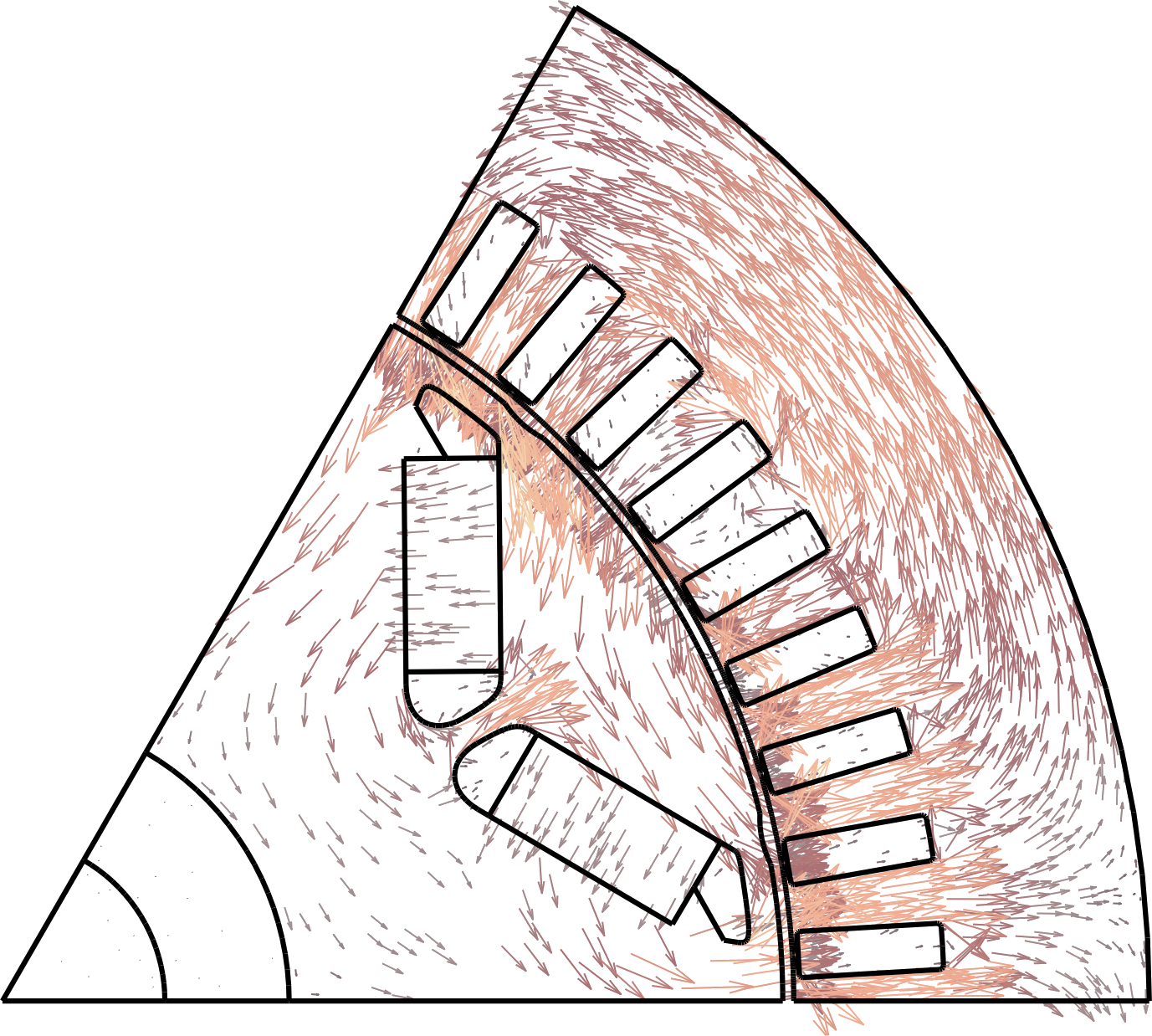

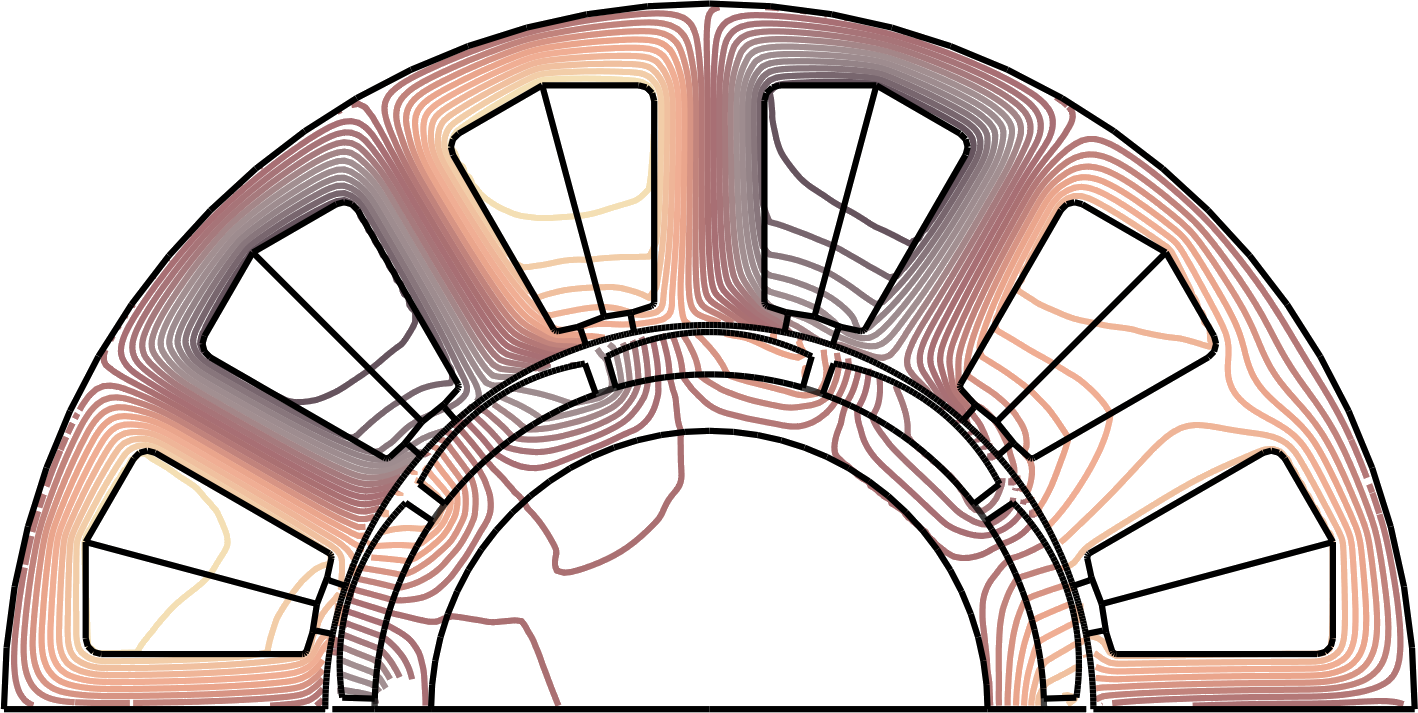

We design bespoke motors tailored to the unique constraints of your traction or robotic application. Our strength lies in our proprietary high-speed simulation framework, which allows us to move far beyond standard analytical methods.

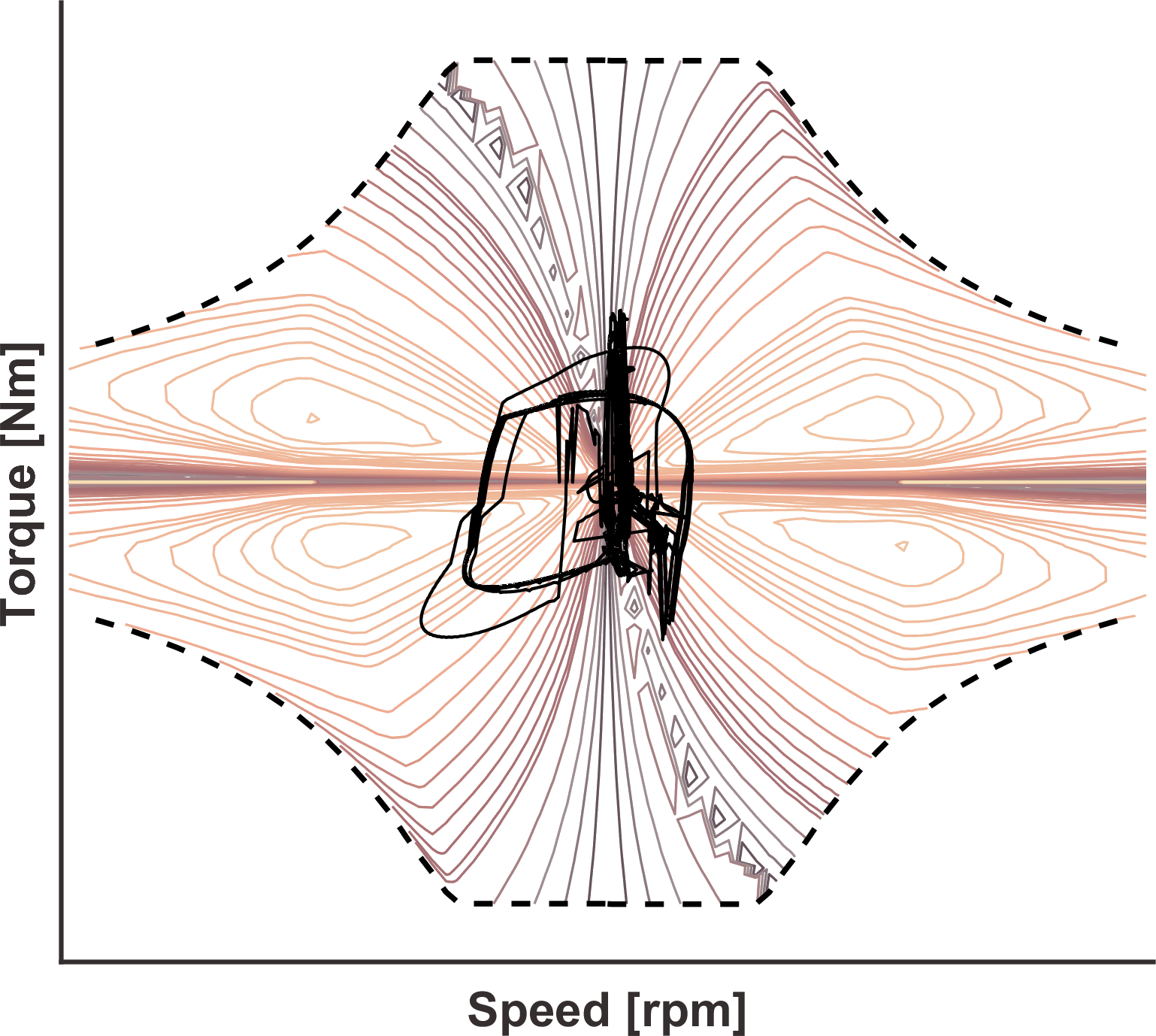

Traction Applications: High-power density designs for EVs, e-bikes, and rail, focusing on efficiency across the entire drive cycle.

Robotics & Actuation: High-torque-to-inertia ratio designs for dynamic response and precision control.

Topologies: Expertise in Radial Flux, Axial Flux, IPM (Internal Permanent Magnet), and SPM (Surface Permanent Magnet) topologies.

Evaluation & Optimization of Existing Designs

If you have an existing motor or an off-the-shelf solution that isn't quite meeting your needs, we can analyze and improve it. We also offer reverse engineering services to benchmark competitor hardware.

Forensic Analysis: We deconstruct existing designs to understand their magnetic and thermal limits.

Sensitivity Analysis: We identify exactly which design variables are holding the performance back and which can be tweaked for maximum gain.

Cost-Down Engineering: By analyzing sensitivity, we can often reduce active material weight (copper/magnets) without sacrificing output, optimizing the unit cost.

Prototyping Support & Validation

A simulation is only valuable if it matches reality. We bridge the gap between the digital twin and the physical hardware, guiding you through the prototyping phase.

Test Bench Correlation: We define validation protocols and correlate physical test data back to our simulation models to ensure accuracy.

Failure Mode Analysis: We predict potential failure points (demagnetization risks, thermal hotspots) before money is spent on hardware.

Supplier Liaison: We assist in communicating technical requirements to suppliers to ensure the prototype matches the design intent.

Preparation for Mass Production

The best motor in the world is useless if it cannot be manufactured at scale. We refine our designs to ensure they are robust, reliable, and cost-effective for high-volume production.

Tolerance Analysis: Using our big data capabilities, we simulate how manufacturing tolerances (air gap variations, magnet strength deviations) will affect performance, ensuring the design is robust enough for mass production.

Material Selection: We balance performance requirements with supply chain reality, selecting steel grades and magnet compositions that are commercially available and scalable.

DFM (Design for Manufacture): We modify geometries to suit winding processes and assembly techniques, reducing scrap rates and cycle times.

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!